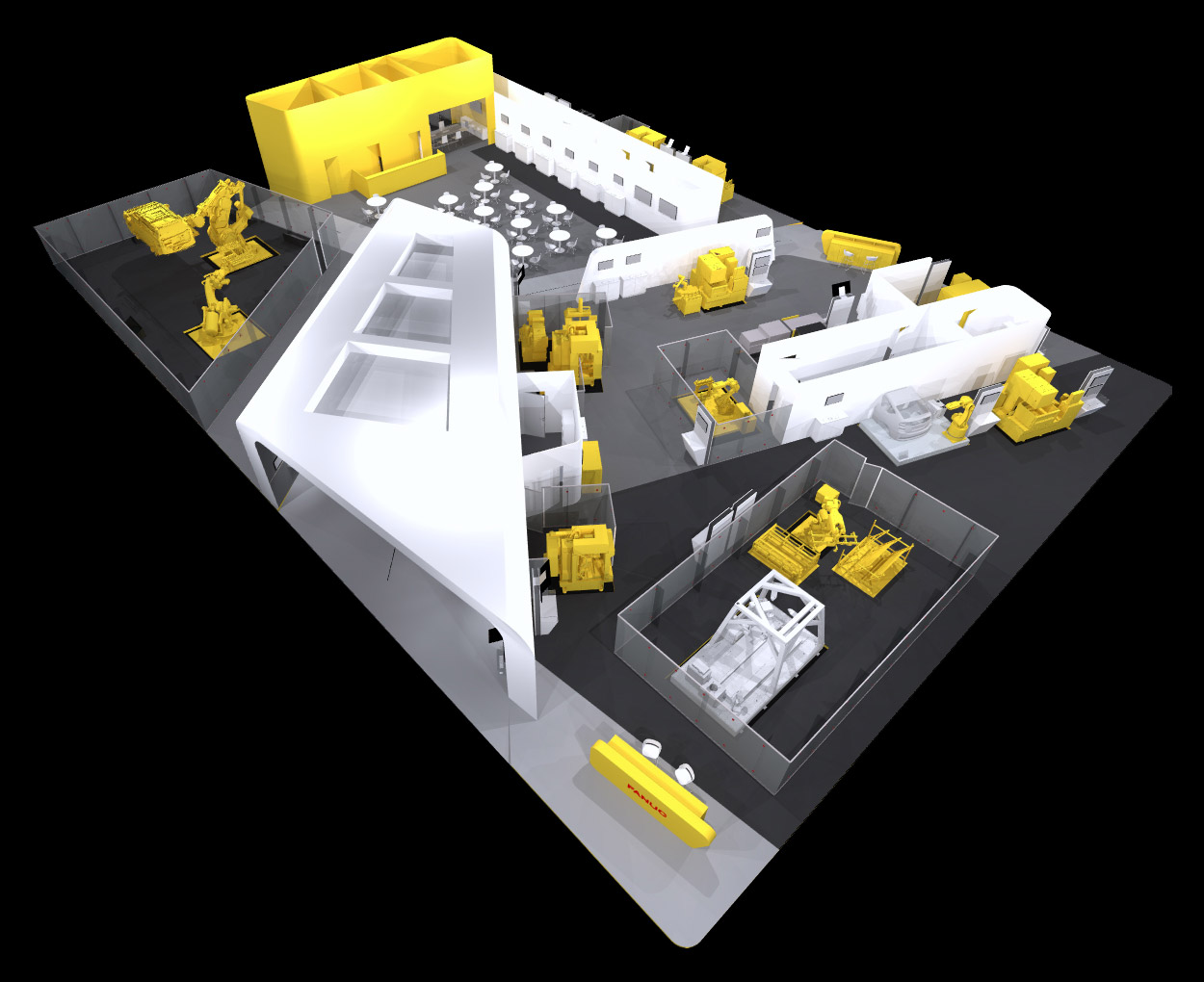

One FANUC solutions

Integration has never been easier. Discover FANUC cell-based solutions connecting CNC machine tools, robotics and software solutions working in unison. Just taking a quick look around you will reveal an innumerable number of objects that have been produced, processed or packaged using industrial automation technologies.

We’re leading the way in the EV market as well. Automating the production process of battery cells is a high priority for vehicle manufacturers and no one has more experience than FANUC.

Download ebook

With the ballooning demand for electric vehicles comes an accelerating demand for automated production of these vehicles and their batteries. Make no mistake about it: Automated production of electric vehicles represents the future for leading-edge automotive manufacturers

In a dedicated fabricating cell containing tending robots, plates can be cut, folded and processed, with workpieces travelling between welding and grinding stations on a conveyor. Once completed the workpiece then moves onto another belt for transportation to a paint spraying cell.

With specialized medical procedures and new advances in technology, the medical devices industry is a burgeoning market. However, medical equipment items and devices are evaluated using higher standards to meet a more stringent set of regulations. Therefore, safety and consistency are key to manufacturing medical supplies and equipment for the products and parts that are in demand.

Applications

EV car body lifting using heavy duty robot M-2000iA/2300

EV car body lifting using heavy duty robot

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

M-2000iA/2300

With its enormous 2.3 t payload, this model is the biggest lifter in the range. Ideally suited to heavyweight material handling applications that require an even stronger wrist.

Widest range of industrial robots

With more than 100 models, FANUC offers the widest range of industrial robots in the world. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options.

NTM success story

NTM can meet growing demands for its products without the need for a nightshift. Much of the heavily lifting is now done safely by the robots instead of employees.

Automated battery cell evaluation

Automated battery cell evaluation

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

M-1000iA

FANUC’s new M-1000iA robot offers full 1000 kg payload capacity with no wrist motion restriction. Notably, the M-1000iA delivers a high-inertia specification for handling large parts within a small footprint system, while unique flip-over capability allows the full work envelope to be available when mounting upside-down.

Widest range of industrial robots

With more than 100 models, FANUC offers the widest range of industrial robots in the world. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options.

Machining of mountain bike components

Machining of mountain bike components

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

ROBODRILL α-D21SiB5 Plus

Learn more about the technical specifications of the ROBODRILL α-D21SiB5 Plus model.

ROBODRILL α-DiB Plus series

The ROBODRILL α-DiB-Plus series of vertical machining centres, which will be available from the beginning of 2022, continues the success story of this machine range. To date, FANUC has delivered around 270,000 ROBODRILL units worldwide. Innovations such as revised spindle variations, new control options, servo drives and mechanical improvements have made the latest ROBODRILL even more effective, reliable, fast and easy to use.

LR-10iA/10

With its 10 kg payload and 1101 mm reach, the new FANUC LR-10iA robot offers a fully enclosed design with IP67 protection rating as standard. A compact design ensures easy installation in tight spaces, alongside the potential for wall and ceiling mounting. In addition, the compatible wrist and base provides interface possibilities with FANUC’s LR Mate 200iD robot series.

Widest range of industrial robots

With more than 100 models, FANUC offers the widest range of industrial robots in the world. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options.

BIG-PLUS

BIG-PLUS is the original dual contact spindle system for 7/24 taper spindle. Thanks to the simultaneous taper and flange contact, the performance is drastically improved.

FANUC ROBODRILL integrate BIG-PLUS BT30 (BBT30) spindle as standard, therefore, together with BIG-PLUS tool holders from BIG-KAISER the machine performs like BT40 taper spindle.

Collet Chuck

All collet chuck from BIG KAISER guarantee less than 3-micron runout at 4D of the cutting tool. Because we know that is the easiest way to reach the better quality and save the running cost. Few micron difference makes huge difference in the running cost. Good machines need good tool holders.

ROBODRILL Educational Package

The new FANUC Educational Package combining our vertical machining centre ROBODRILL with our latest collaborative robot CRX-10iA. Hands-on learning on an automated CNC milling machine for your future in production.

Handling of EV Battery parts

Handling of EV Battery parts

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

R-2000iD/165FH

Compact and high speed with a slim wrist and arm, the R-2000 is an all-rounder that is designed for all material handling applications and spot welding.

3D Vision Sensor

Automating your processes using this object-recognition technology represents an effective way of increasing productivity and reducing costs on a vast range of general material handling applications.

iRVision

iRVision is FANUC’s unique, fully robot integrated visual detection system enabling the robots to see in order to manage production settings in a faster, smarter and more reliable way.

Widest range of industrial robots

With more than 100 models, FANUC offers the widest range of industrial robots in the world. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options.

Wire-cutting of electric automotive parts

Wire-cutting of electric automotive parts

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

ROBOCUT α-C600iC

Find out more about the can-do all-rounder ROBOCUT α-C600iC.

ROBOCUT α-CiC series

FANUC’s ROBOCUT α-CiC wire EDM machine series impresses with many new developments. For instance, we further enhanced machine rigidity by strengthening the mechanical structure, providing the basis for more precise machining and even higher repeatability. Learn more.

Collaborative headlight mounting

Collaborative headlight mounting

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

CR-35iA

The 35kg payload collaborative robot can relieve workers from heavy lifting and positioning in a range of industries. That way they will be free to do the more skilled work. Thanks to the built-in anti-trap protection and soft rubber skin it is safe to work alongside the robot.

Cobots

Imagine a world without safety fences, a world in which humans work side-by-side with robots. In this world, robots would execute all strenuous tasks, enabling humans to dedicate their precious time to lighter, more skilled or demanding tasks.

Cobot eBook

Human – Robot collaboration is getting more viable every day thanks to the ever increasing ability of collaboration. Putting collaborative robots to practice may sound complicated at first but this eBook will show 7 steps to make this process easier.

Picking and handling of single battery cells

Picking and handling of single battery cells

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

SR-12iA

SCARA robots are ideally suited to assembly, pick and place, inspection and packaging applications. All FANUC SCARA robots operate in a 360° envelope and, by virtue of their pedestal-mount design, occupy a small space-saving footprint. Integrated services prevent the risk of snagging.

DR-3iB/8L

Specifically designed to maximise speed and versatility on high-speed small part handling and picking operations across a range of industries including food, pharmaceutical and electronics.

3D Vision Sensor

Automating your processes using this object-recognition technology represents an effective way of increasing productivity and reducing costs on a vast range of general material handling applications.

iRPickTool

FANUC iRPickTool visual line tracking technology significantly enhances productivity by providing single or multiple robots with the ability to identify and pick and place items on a moving conveyor belt.

iRVision

iRVision is FANUC’s unique, fully robot integrated visual detection system enabling the robots to see in order to manage production settings in a faster, smarter and more reliable way.

SCARA eBook

Download the free FANUC ebook dedicated to SCARA robots now! You will find market data, information on new solutions and much more!

Widest range of industrial robots

With more than 100 models, FANUC offers the widest range of industrial robots in the world. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options.

Automated mould insertion

Automated mould insertion

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

ROBOCUT α-C400iC

Find out more about the compact match for micro machining ROBOCUT α-C400iC.

ROBOCUT α-CiC series

FANUC’s ROBOCUT α-CiC wire EDM machine series impresses with many new developments. For instance, we further enhanced machine rigidity by strengthening the mechanical structure, providing the basis for more precise machining and even higher repeatability. Learn more.

CRX-10iA/L

The CRX-10iA/L is highly protected against dust or oil leakages common in industrial environments and fully complies with ISO 10218-1 safety standards. Because of its very low weight, the CRX can be easily installed in a broad range of applications such as automated guided vehicles (AGV).

Cobots

Imagine a world without safety fences, a world in which humans work side-by-side with robots. In this world, robots would execute all strenuous tasks, enabling humans to dedicate their precious time to lighter, more skilled or demanding tasks.

Cobot eBook

Human – Robot collaboration is getting more viable every day thanks to the ever increasing ability of collaboration. Putting collaborative robots to practice may sound complicated at first but this eBook will show 7 steps to make this process easier.

iRVision

iRVision is FANUC’s unique, fully robot integrated visual detection system enabling the robots to see in order to manage production settings in a faster, smarter and more reliable way.

Collaborative Educational Package

FANUC collaborative educational package: get up close and personal with collaborative robot learning. The CRX educational package presents a new take on robot training. It features a FANUC CRX-10iA collaborative robot and all the functions required to teach core programming skills.

Automated medical parts production

Automated medical parts production

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

LR Mate 200iD

It combines best-in-class robot weight-load capacity with standard IP67 protection and outstanding FANUC quality.

ROBOSHOT α-S50iB

With models capable of exerting clamping forces from 150 kN to 4500 kN, FANUC ROBOSHOT is ideally suited to a diverse range of straightforward as well as sophisticated injection moulding tasks. Learn more about the ROBOSHOT α-S50iB.

ROBOSHOT α‑SiB Series

With the release of the new FANUC ROBOSHOT α-SiB series of injection moulding machines, FANUC is building on its already strong market position in the European plastics industry. Numerous enhancements to the machine’s control, software and performance provide customers with countless advantages while maintaining the FANUC ethos of high performance, high sustainability and ease-of-use through its all-electric design.

QSSR

Connect your CNC and the robot easily with just one Ethernet cable and monitor the robot status on the CNC display screen. The robot motion is programmed with G-code and no knowledge of robot programming is required.

Robotization handbook

Discover how to maximise your productivity using robotic machine-tending solutions. Robotisation will help you to increase turnover, use skilled labour more efficiently, improve quality and increase flexibility.

Widest range of industrial robots

With more than 100 models, FANUC offers the widest range of industrial robots in the world. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options.

Production of head-up display units

Production of head-up display units

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

ROBONANO α-NMiA

0.1 nm programming command, the latest FANUC standard CNC and motors, an oil hydrostatic bearing, linear motors, an active damping system and an HMI screen for operating peripheral devices.

ROBONANO α-NTiA

The a-NTiA model is the turning variant of the ultraprecision machines ROBONANO. ROBONANO has a positioning command resolution of 0.1 nanometre which is required to achieve optical quality surface finish.

High-accuracy drilling cell

High-accuracy drilling cell

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

M-800iA/60

Robust construction, high rigidity and iRCalibration Signature technology included as a standard makes the model the most precise in FANUC history. The M-800iA/60 offers outstanding precision without slowing down the production process.

Force Sensor

Equipped with a Force Sensor, robots are capable of realising assembly, contouring and measuring tasks across a vast number of applications. 4 different sizes of Force Sensors are available for 6-axis robots with payload capacities up to 250 kg.

Widest range of industrial robots

With more than 100 models, FANUC offers the widest range of industrial robots in the world. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options.

High precision surface quality

High precision surface quality

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

ROBODRILL α-D21MiB5 Plus ADV

Learn more about the technical specifications of the ROBODRILL α-D21MiB5 ADV Plus model.

ROBODRILL α-DiB Plus series

The ROBODRILL α-DiB-Plus series of vertical machining centres, which will be available from the beginning of 2022, continues the success story of this machine range. To date, FANUC has delivered around 270,000 ROBODRILL units worldwide. Innovations such as revised spindle variations, new control options, servo drives and mechanical improvements have made the latest ROBODRILL even more effective, reliable, fast and easy to use.

LR Mate 200iD/7L

Fast at handling small payloads, this compact multi-purpose industrial robot offers an enhanced reach of 911 mm and a payload of up to 7 kg.

Widest range of industrial robots

With more than 100 models, FANUC offers the widest range of industrial robots in the world. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options.

ROBODRILL Educational Package

The new FANUC Educational Package combining our vertical machining centre ROBODRILL with our latest collaborative robot CRX-10iA. Hands-on learning on an automated CNC milling machine for your future in production.

DDR-T Table autotuning

DDR-T Table autotuning

Get the full digital experience. From the screens in Milan directly to your screen in front of you. Watch the video and receive more detailed information about this EMO exhibit.

FS-31iB Plus

Boosting the widest range of CNC systems in the industry, FANUC provides everything you will ever need for your CNC – from best value controls with powerful functionality to high-performance control systems for complex machines.

DDR

The FANUC ROBODRILL DDRiB makes the perfect additional axis for your ROBODRILL. Benefits include an indexing time of just 0.55 seconds, ultrafast clamping and a clamp torque of 700 N-m. Extremely precise and reliable, the DDRiB also offers unbeatable value for money

DDR-T

Depending on the application, we can equip your ROBODRILL with an extremely rigid DDR-T trunnion system that features all the benefits of the DDR rotary table and includes a support spindle and L-brackets.

Collet Chuck

All collet chuck from BIG KAISER guarantee less than 3-micron runout at 4D of the cutting tool. Because we know that is the easiest way to reach the better quality and save the running cost. Few micron difference makes huge difference in the running cost. Good machines need good tool holders.

BIG-PLUS

BIG-PLUS is the original dual contact spindle system for 7/24 taper spindle. Thanks to the simultaneous taper and flange contact, the performance is drastically improved.

FANUC ROBODRILL integrate BIG-PLUS BT30 (BBT30) spindle as standard, therefore, together with BIG-PLUS tool holders from BIG-KAISER the machine performs like BT40 taper spindle.